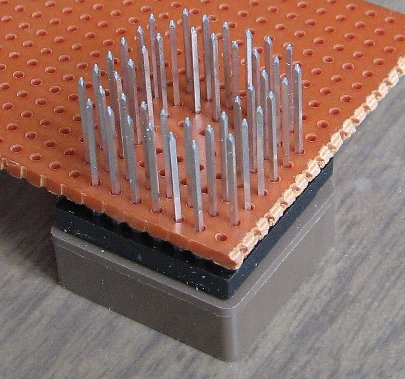

(This improves performance too, as connections get shorter, reducing inductance.)

You can see one in the photo above, although that one is for an IDC (insulation-displacement connector) to plug in a ribbon cable for a parallel printer.

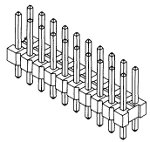

This is a picture of a 44-pin one I have from Berg Electronics, McKenzie Socket Division. These are no longer avaiable but you can get (Dec 2020) 44-pin Winslow ones at RS Online here, and 32-pin ones here. They're basically the same thing. Note that these do go into standard prototyping board with holes on .100" centers. I grabbed a tiny piece of cheap prototyping board to take this picture:

Jeff Laughton gives a couple of other ways to do PLCC WW sockets on the 6502.org forum at http://forum.6502.org/viewtopic.php?p=37202#p37202, and just a couple of posts down in the same topic, at http://forum.6502.org/viewtopic.php?p=37206#p37206.

If you lay out a PC board, use PLCCs and other SMT parts. They're not as hard to solder as you might think. Soldering SO and SOJ packages by hand does not require soldering one lead at a time. You tack two oposite corners, then starting at a third corner, just flood an entire side with solder, using a tip that covers two or three leads at once, leaving lots of bridges, then hold it vertically and go from top to bottom again with the iron, and all the excess solder comes off on the iron, leaving an even amount of solder on every pin, just right. It's amazing how easy it is. Extra flux helps, but then you might need a way to clean the resulting gooey mess off. I have a more complete description here (on the forum), and there's a picture two posts above that.

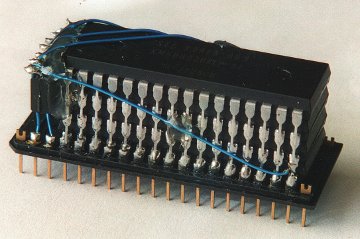

The time to do this is when most of the pins are common to the two or more ICs, as is the case with memory. Stacking them like this also gives the benefit of reducing the connection length and capacitance. There's more of a collection of this kind of thing in this forum topic. Some examples are extreme! :D